LT product line

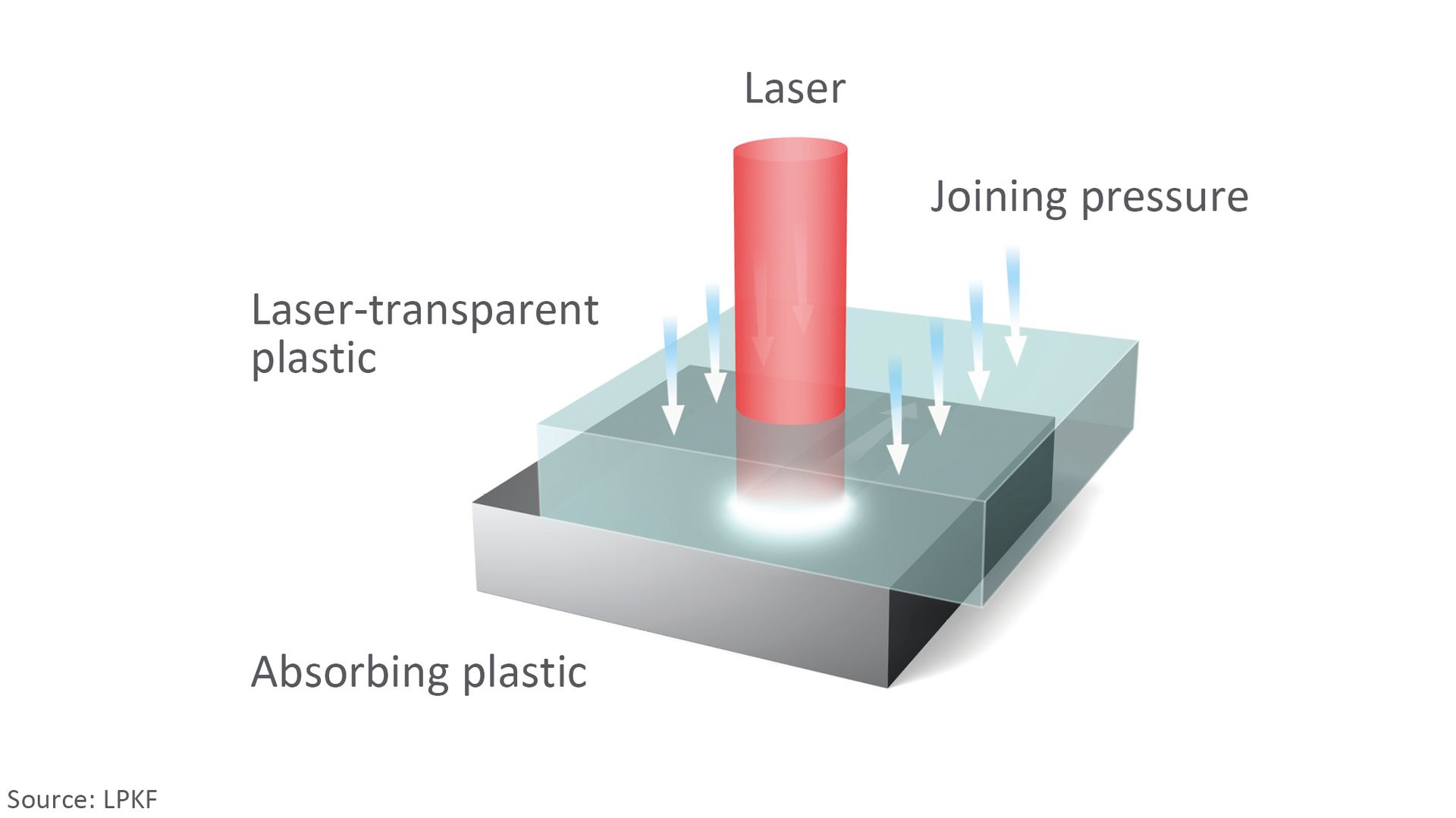

Laser transmission welding, in which two grades of thermoplastic materials are joined together, is a process that has been industrially established for years: The transparent joining partner is penetrated by the laser, while the absorbing one is heated. The absorbent plastic melts the transparent joining area and is pressed together with a suitable fixture. Application examples can be found in medical engineering, automotive, electronics and even household appliances

Typically, four variants can be distinguished in the laser welding of plastics: Contour welding, quasi-simultaneous welding, simultaneous welding and mask welding. The most important distinguishing features are the type of energy input and the beam shaping.

The selection of a variant depends on criteria such as the complexity of the joint geometry (2D or 3D), the quantity to be produced, the available investment costs, and the requirements for the weld properties. Laser-based joining of plastics has many advantages and has now replaced classic processes such as gluing and ultrasonic or vibration welding in many industries.

Laser Transparency

Laser welding is a non-contact welding process that is used for very tight tolerances of the components to be joined.

For the different process variants, we offer you optimised and customised laser welding additives of our “LT” product group.

These are available to you as a pure additive or already in combination with color.

Laser Transparency

In the so-called black/black arrangement, the lower part is usually made absorbent by adding carbon black. Carbon black absorbs optimally both in the visible and near-infrared range, so that all common lasers can be used. The demanding part is to make the upper part black for the eye and transparent for the laser.

Recording with an infrared camera

Recording with a conventional camera

Guaranteed Success

One of the key factors for a high-quality welded joint is the coloration or pigmentation of the components. An optimal basis for laser transmission welding can be provided by a suitable choice of polymer and additional pigment in order to meet the visual and laser-specific properties. We have many years of experience in the production of these laser-transparent and also polyamide-based masterbatch formulations.

Laser-transparent Materials

Advantages

- Invisible welding seams

- Localised energy input allows welding of sensitive components

- No formation of abrasion particles or adhesive residues

- Welding seams are possible in the vicinity of electronic components

- Vibration-free welding method

Masterbatches – Custom-made for your Product Ideas

You want to know how we meet the requirements specific to your industry? Contact us and find out what we can do for you.

Contact